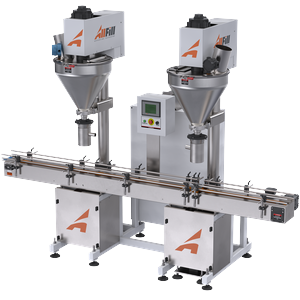

Model TAA

Fillers

All-Fill’s Model TAA automatic auger fillers are designed for high speed and high volume, dispensing typically encountered in vertical form-fill-seal, cup filling, or other applications requiring dual-position filling. Each unit is designed exactly to your requirements. Our filling application specifies each Model TAA auger filler. The center distance between the 2 augers can range from as little as 2″ to well over 6″. Forming tube diameter, funnel length, and height will match your specific equipment. Tooling and accessories, such as augers, collector funnels, cutoffs, etc., are supplied to best suit your product, production rates, and accuracy levels.

Specifications

-

ConstructionPainted steel base. Anodized aluminum. Stainless steel contact parts. Tubular frame with removable access doors. Includes mechanical jack to raise/lower fill head. Painted aluminum head castings with one-piece stainless steel covers. Heavy-duty clutch-brakes or servo direct drives.

-

Production RatesSpeeds ranging up to 60 CPM, depending on application and fill size

-

Control FeaturesA speed adjustable belt drive and continuously-operating fill motor provides the torque and high cycle rates necessary for production filling. Product level control, Slow speed agitation, Motor starters and transformer, Adjustable frequency Vibration to settle product in container, Accepts standard All-Fill accessories, In-Line All-Fill Checkweigher with feedback to filling heads for instantaneous adjust- ment of filled amounts

-

Storage100 product memory

-

Hopper Capacity4 cu. ft. with dustproof cover and common infeed duct

-

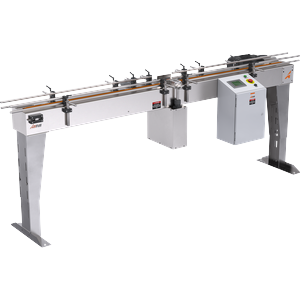

ConveyorStainless steel conveyor channel with dual-strand stainless steel block conveyor chain or plastic tabletop conveyor. Adjustable guide rails and variable speed conveyor drive. Pneumatic container indexing with round end. Cone point, wedge stop or pressure stop adjustable indexing pins.

-

Electrical Requirements208/230/460V; 3-Phase; 60HZ. Standard

-

Pneumatic Requirements4 SCFM @ 60 PSI

-

ChangeoversMostly toolless

-

OptionsStainless steel construction. Slow-speed agitation with separate motor. Reducing gearbox and drive components. Includes stainless steel slow speed agitator blade. Adjustable speed. Jogging container vibrator to settle and distribute product in container. Pneumatic or servo container lift to raise/lower container to funnel. Container lift for bottom-up filling.

All dimensions and specifications are subject to change without notice. Consult your sales representative or email us at info@allfill.com for exact information prior to purchase.

Common Applications

-

Fertilizer Pellets

-

Toner Powder

-

Cat Litter

-

Small Pet Food

-

Whole & Ground Coffee

-

Sugar

-

Jimmies & Sprinkles

-

Plant Foods

-

Food Powders

-

Plastic Granules

-

Ground Spices

-

Flake Spices

-

Fine Cut Tobacco

-

Flour Powder

-

Whole & Ground Pepper

-

Detergent Powder

-

Infant Formula

-

Cake Mix

-

Pancake Mix

-

Cement Powder

-

Cocoa Powder

-

Matcha Powder

-

Cosmetic Powder

-

Curry Powder

-

Protein Powders

-

Turmeric Powder

-

Parsley & Oregano

-

Grains

-

Seeds

-

Chia Seeds

-

Grass & Fennel Seeds

-

Salt Products

-

Rice Products

-

Lentils

-

Breadcrumb

-

Brown Sugar