Our Company

All-Fill designs, manufactures, services and supports a line of packaging machinery including; auger, piston, vibratory & cup fillers, bagging, checkweighing, labeling & bottle unscrambling equipment. We are committed more than ever to becoming the single source for all of your packaging machinery solutions.

Auger Fillers

The Auger Filler is the foundation of All-Fill's product line and machine that the company was built on. Our Auger Filler is second to none and continues to be the standard in the industry. Learn more about and Semi-Automatic and Automatic models.

Auger Fillers

Vibratory Fillers

All-Fill vibratory fillers provide you the perfect blend of accuracy, speed and versatility across our comprehensive line of net weigh fillers. Our vibratory line excels in the handling of difficult and delicate whole products. All-Fill vibratory fillers are designed to handle your unique products along with precise weights.

Vibratory Fillers

Cup Fillers

The All-Fill series of volumetric cup filler systems can be used to dispense a variety of dry free-flowing products such as beans, rice, pet food, pop-corn, candy, seeds, grains, nuts and many more without any product degradation.

Cup Fillers

Piston Fillers

All-Fill liquid filling machines combine precision, speed and versatility in liquid filling technology designed for liquids, pastes, creams and other viscous products. Learn more about and Semi-Automatic and Automatic models.

Piston Fillers

Checkweighers

Formerly known as Alpha Checkweighers, All-Fill Checkweighers offer a comprehensive range of online, in production weighing and weight control equipment. Our machines can be adapted to handle virtually every package, bag, carton, box and bottle and sold as standalone or integrated systems with other All-Fill equipment.

Checkweighers

VFFS Baggers

Formerly known as Avatar, All-Fill's line of Vertical Form Fill & Seal machines is your complete bagging solution. Our machines are engineered to accommodate a variety of bag styles for virtually any application and meet your speed requirements.

VFFS Baggers

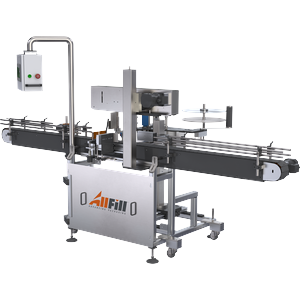

Labelers

Formerly Re-Pack, All-Fill manufactures a variety of industrial labeling systems to accommodate most budgets and production requirements. Available in Semi-Automatic with table top options, or Automatic designs with integrated conveyor.

Labelers

Unscramblers

Formerly Palace Packaging, All-Fill manufactures a line of high speed container handling and bottle unscrambling machines to keep up with your packaging demands. Bottle unscramblers process bulk amounts of most bottle styles, and orient them onto a conveying line for filling.

UnscramblersFeatured Machines

Custom Machines

All-Fill has realized that one size does not fit all. Custom Solutions represents our ability to provide extensive design and fabrication expertise for packaging equipment. Your applications will be thoroughly analyzed and an appropriate solution will be developed, designed, and manufactured to exceed your packaging demands.

Custom Machines

Our Team

No matter the business, the key to success is hard work, determination and good people. Never was this truer than the beginning, the early years in which the first employees were laying the structural foundation and required work ethic for long term success and growth. All-Fill wouldn't be where it is today without the extraordinary group of employees that have called All-Fill home for many years.

Our Team

Parts Support

All-Fill machines are designed using the most innovative controls and the highest quality parts and components. Our parts department provides quality support in a timely manner to reduce your downtime and stocks most parts for quick delivery. From mechanical assemblies, electronic components, tooling, machine accessories and software, we have the parts you need on standby.

Parts Support

Our History

Founded in 1969, All-Fill’s initial offering was an economical, highly reliable auger filler for powder and liquid filling that featured a simplified, “no nonsense” design. It could accurately dispense product with a minimum amount of setup, maintenance or operator intervention. With a legacy that spans more than 50 years and three generations of Edgintons, All-Fill machines continue to revolutionize the industry.

Our History

AFI West

The need for speed, accuracy, and reduced waste has never been more critical than now. We provide exceptionally rugged, reliable, and accurate equipment to help you meet increasing demands. All-Fill is happy to announce that we are heading west! In late summer of 2020, we will be opening a new sales and support center in Scottsdale, Arizona to better serve our west coast clients and expand operations.

AFI West

Careers

We are truly committed to providing our staff with a rewarding and innovative work environment. All-Fill has a legacy of being an industry leader, and continues to invent new ways to work faster and smarter, leading to a wealth of career opportunities. We’re always looking for dynamic, driven individuals to join our growing and team.

Careers

Contact Us

All-Fill’s packaging machinery is available worldwide for almost any product and industry. Our global presence means uncompromising service and support, no matter what or where your needs are. Reach out today to discuss your project with our international sales team. Our more than 50 years of engineering expertise combined with our industry leading field support makes us a leader in the industry.

Contact Us

Service Support

We understand downtime and its effect on your bottom line. Packaging machinery is only as strong as its service and support system. If you run into challenges, All-Fill’s Service team consists of 15 full time service employees with over 150 years of combined experience in the packaging industry. Our team can train, install, and troubleshoot any All-Fill machinery.

Service SupportOur Solutions

You name it, there’s a good chance we’ve filled that, or something similar. If you have a question about your product, reach out and we can help you find out what machine might be best for your needs. Or check out our Find your machine tool to learn more about other applications for your coffee production. Also, we offer complimentary product testing at onsite product test lab.

Request A Consultation

From design through testing, installation and beyond, we work tirelessly to ensure your equipment is running at peak performance and maximizing your application. To learn more about our machines, reach out to set up a free consultation with our in-house experts.