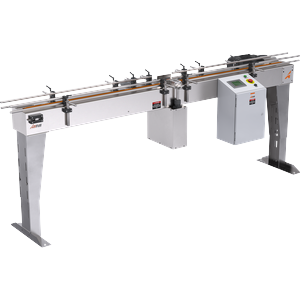

Model B/S

Fillers

All-Fill’s Model BS Pouch Auger Filling System fills small pouches with products. This is a “bulk and dribble” application.

The operator attaches the small pouch onto a mounting clip. When the empty pouch is in place, a tare weight is established. A pneumatic lift then lifts the empty pouch from the scale to its bulk-fill position (Approximately 1″). A bottom-up fill occurs, ensuring that the amount of dust caused by the product in motion will be minimized. As the bulk fill is in progress, the lift lowers to the scale at a slower speed. A bulk weight is taken at the scale. The lift then raises back up and the bottom-up dribble fill commences. The lift again lowers to the scale, and a final weight is taken. If it is underweight, a second dribble fill occurs.

The scale also has a “real-time” weight function to guarantee flexibility and accuracy.

Specifications

-

ConstructionPainted aluminum base. Stainless steel contact parts. Optional sturdy tubular steel frame to support filling head and conveyor. Includes mechanical jack to raise/lower fill head. Aluminum head castings with one-piece stainless steel covers. Heavy-duty clutch-brakes or servo direct drives.

-

Production RatesSpeeds depending on product and operator

-

Control Features7" color touchscreen HMI. A speed adjustable belt drive and continuously-operating fill motor provides the torque and high cycle rates necessary for production filling. Product level control. Slow speed agitation. Motor starters and transformer. Adjustable frequency vibration to settle product in container. Accepts standard All-Fill accessories. In line All-Fill Checkweigher with feedback to filling heads for instantaneous adjustment of filled amounts. Adjustable guide rails. Variable speed.

-

Storage100 Product memory

-

Hopper Capacity2 cu.ft. hopper with dustproof cover and common infeed duct, optional 4 cu. ft.

-

Electrical RequirementsFill Motor Input: 208/230/460V; 3-Phase; 60HZ. Standard Controls: 115V 50-60 HZ. Other ratings available upon request.

-

Pneumatic RequirementsApplication dependent

-

ChangeoversMostly tool-less

-

OptionsSlow-speed agitation with separate motor. Reducing gearbox and drive components. Includes stainless steel slow speed agitator blade. Adjustable speed. Jogging container vibrator to settle and distribute product in container. Pneumatic or servo container lift to raise/lower container to funnel. Container lift for bottom-up filling. Product level control. Lift and hold quick drop features. Adjustable stroke to 7". Product level control. Production counter.

All dimensions and specifications are subject to change without notice. Consult your sales representative or email us at info@allfill.com for exact information prior to purchase.

Common Applications

-

Fertilizer Pellets

-

Toner Powder

-

Cat Litter

-

Small Pet Food

-

Whole & Ground Coffee

-

Sugar

-

Jimmies & Sprinkles

-

Plant Foods

-

Food Powders

-

Plastic Granules

-

Ground Spices

-

Flake Spices

-

Fine Cut Tobacco

-

Flour Powder

-

Whole & Ground Pepper

-

Detergent Powder

-

Infant Formula

-

Cake Mix

-

Pancake Mix

-

Cement Powder

-

Cocoa Powder

-

Matcha Powder

-

Cosmetic Powder

-

Curry Powder

-

Protein Powders

-

Turmeric Powder

-

Parsley & Oregano

-

Grains

-

Seeds

-

Chia Seeds

-

Grass & Fennel Seeds

-

Salt Products

-

Rice Products

-

Lentils

-

Breadcrumb

-

Brown Sugar