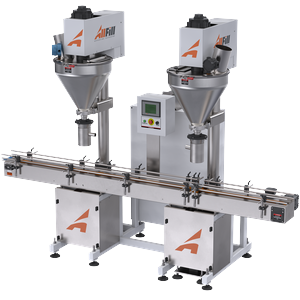

Series 1500

Fillers

The 500 Series Volumetric Piston Filling Systems are designed for the completely automatic, multiple position, in-line dispensing of liquids and pastes in volumes to match specific production requirements. Precision bored, heavy-walled metering cylinders dispense product at accuracies of ±0.25%.

All product contact parts constructed of stainless steel/food grade plastics for sanitary operations or use with corrosive materials. Series 1500 filling systems are available with a motorized conveyor and indexing package for integrated container handling and positioning. A separate unique variable speed feature provides precise “no spill” control to eliminate splashing.

Specifications

-

Production RatesVaries dependent on fill size and amount of nozzles, 2, 4, 6 & 8 nozzle configurations available

-

FeaturesMulti-stroke control with counter controls. Container indexing to regulate container movement and positioning. Variable speed 8’ stainless steel conveyor; includes container indexing. Level control for consistent product re-supply. Footswitch for initiation of fill cycles. Air logic controls/air motor for hazardous locations. Nozzle side shift drip tray.

-

Nozzle SizesA range of delivery nozzles allows exceptionally clean cut off of almost any liquid or semi liquid product.

-

Fill Volumes1.69 oz. to 1 gal., with solid particles up to 7/8”

-

Cylinder SizesVariety of sizes from .75" to 6.75"

-

Accuracy±0.5%, typical

-

Product SupplyPolished, stainless steel conical 13 gal. capacity hopper or 90° inlet adapter with 5’ of tubing for supply from bulk source

-

OptionsAir logic controls. Diaphragm cutoff. Container indexing packages. Bottom-up filling. Insulated/heated hoppers. Tri-clover fittings for hopper and nozzle connections (pharmaceutical applications). Continuous recycling with toggle switch. Suck back design or positive cut-off. A range of portable stainless steel stands - low level, standard and heavy-duty with adjustable height. Multiple stroke mechanism for larger fills.

-

Options3 types of product valves available – standard rotary, large rotary and check valve, optional sub-surface filling mechanism and nozzle for filling foaming products. Air motor for hazardous locations.

-

ControlsFill Volume: stroke adjustment knob at rear of unit, fill & recharge speed: adjustment, indexing, conveyor speed

-

Pneumatic80 PSI @10 SCFM

All dimensions and specifications are subject to change without notice. Consult your sales representative or email us at info@allfill.com for exact information prior to purchase.

Common Applications

-

Apple Sauce

-

Jams / Jellies

-

Tomato Paste

-

Motor Oil

-

Ketchup

-

Mustard

-

Pesto / Relish

-

Peanut Butter

-

Cosmetic Pastes

-

Bubble Bath

-

Nail Polish

-

Body Scrubs

-

Yogurt

-

Ointments / Medicine

-

Petroleum Products

-

Shampoo & Hair Gel

-

Food Sauces

-

Building Adhesives

-

Epoxies / Adhesives

-

Liquid Wax

-

Lotions

-

Glue

-

Raw Dough

-

Honey

-

Cooking Oil

-

Hummus

-

Pâté

-

Salad Dressings

-

Butter / Margarine

-

Fruit Juices