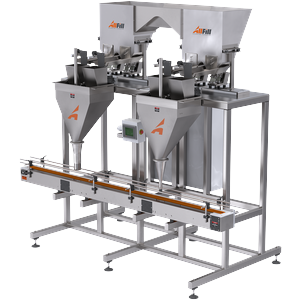

ST/Series

Fillers

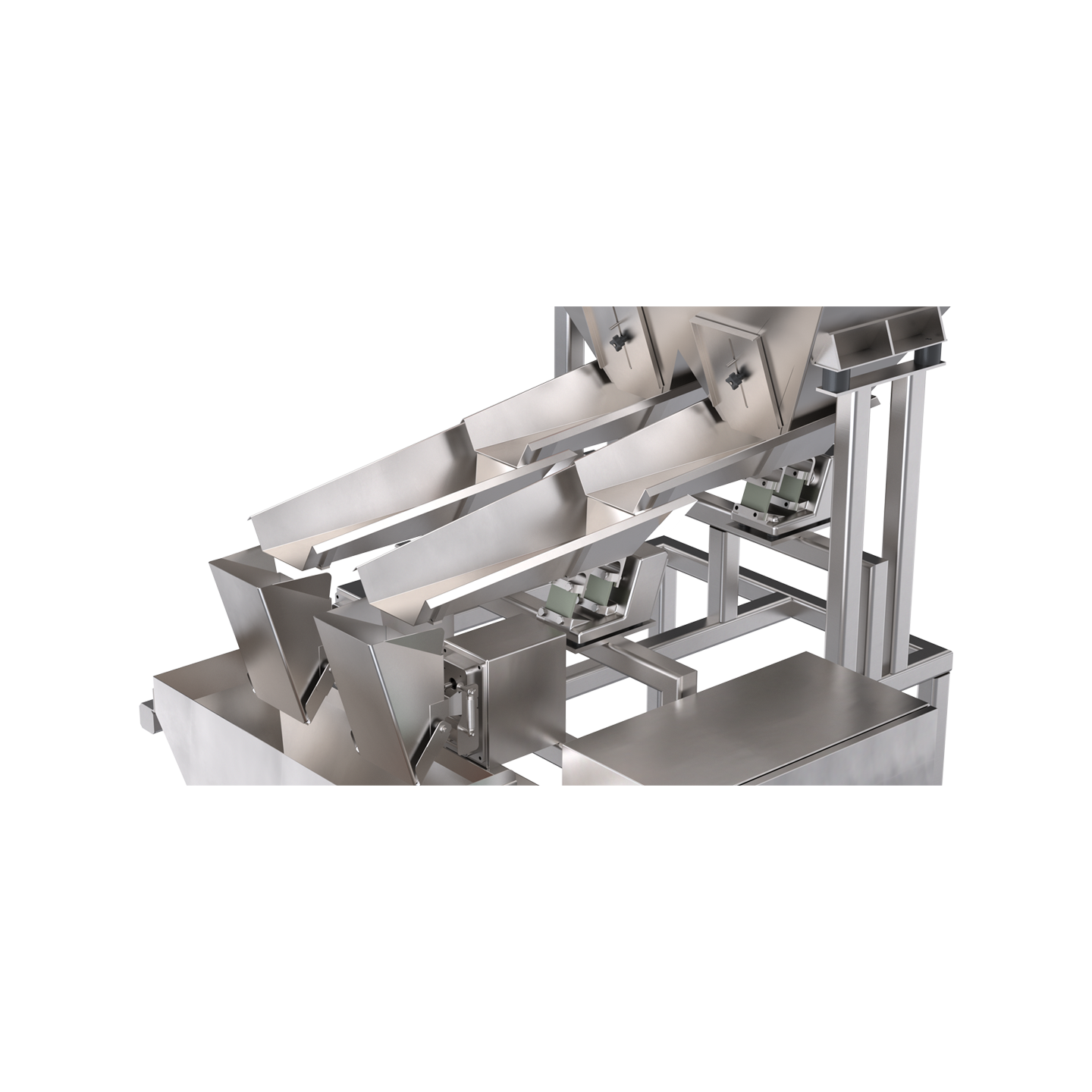

The ST/Series of vibratory feeders is the filling solution for the precise feeding and weighing of free-flowing and occasionally non free-flowing products. Vibratory fillers are able to move and fill products such as snack foods, hardware, and more without causing damage to the product. The ST/Series is available in multiple lanes as non-cascading, cascading, or bulk and dribble. Speeds range up to 60 containers per minute with filling weights of 0.5 oz to 10 lbs. The ST/Series allows products to be precisely conveyed, weighed, and dispensed at accuracies of ± 0.5 to 1%.

Specifications

-

ConstructionAll stainless steel, available in 1-4 lane configurations for semi-automatic of automatic models

-

Production RatesSpeeds ranging up to 15 CPM per lane, depending on fill size.

-

ControlsEmbedded controller, 10.00" color touch screen HMI, foot pedal initiation

-

Control FeaturesIndividual control of all settings. Alphanumeric product naming. Containers per minute readout. Automatic tare. Batch count readout. Users / Maintenance / Supervisor Login. Statistical analysis of a shift run. Weigh units of measure. Weight or count mode.

-

Hopper CapacitySupply hopper capacity of 1.5 cu. ft. standard, other options and sizes available: hopper extensions and covers

-

Weigh Bucket Sizes3 liter standard, 7 Liter or 11 Liter options available

-

Machine DimensionsFeed pan widths from .5" to 5.0" wide

-

Storage100 product memory

-

Electrical Requirements120V/1ph/60HZ standard (other voltages available)

-

Changeovers"Tool-less” disassembly of hopper, weigh bucket and funnel for ease of cleanup and changeover

-

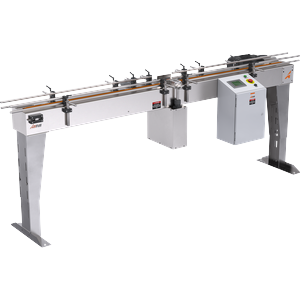

OptionsConveyor. Indexing and automation packages. Partition hopper for ingredient mixing. Nylon coating and dimpled contact surfaces. Statistical package (USB). Low pressure washdown designs. Variety of fill accessories. Nozzles or chutes. Electric dribble feed gate. Heavy-duty vibrator. Additional lanes for increased production. Product level control to signal infeed device. Hopper cover. Integration with OEM. 316 stainless steel contact and quick removal parts available.

All dimensions and specifications are subject to change without notice. Consult your sales representative or email us at info@allfill.com for exact information prior to purchase.

Common Applications

-

Almonds

-

Cheese Products

-

Dried Fruit

-

Tobacco Products

-

Wax Beads

-

Cereal Products

-

Raisins

-

Hop Pellets

-

Pecans

-

Whole & Ground Coffee

-

Cloves

-

Olives

-

Granules

-

Dehydrated Meats & Jerky

-

Fish Food

-

Tea Leaves

-

Peas & Legumes

-

Pet Food

-

Shredded Cheese

-

Wood Chips

-

Chocolate Truffles

-

Cherries

-

Potato Chips

-

Metal Hardware

-

Dental Picks

-

Coated Candy

-

Granola

-

Cookies

-

Glitter Products

-

Fertilizer Granules

-

Plastic Hardware

-

Cannabis

-

Fasteners

-

Wood & Feed Pellets

-

Jimmies & Sprinkles

-

Plant Foods

-

Chocolate Chips

-

Wrapped Candies

-

Animal Treats

-

Tortilla Chips

-

Coated Gummies

-

Soft Coated Candies

-

Glass Beads

-

Pretzels

-

Popcorn

-

Pasta Products

-

Beans

-

Whole Peppercorns

-

Chia Seeds

-

Grass & Fennel Seeds

-

Fresh & Frozen Fruit

-

Chickpeas

-

Minced & Whole Garlic