Blog

MAKING ROTARY CHANGE-OVERS EASY

May 17th, 2016

Volumetric rotary auger fillers are one of the fastest filling machine applications we offer here at All-Fill. If ran correctly these machines can produce outputs of over 300 containers per minute!

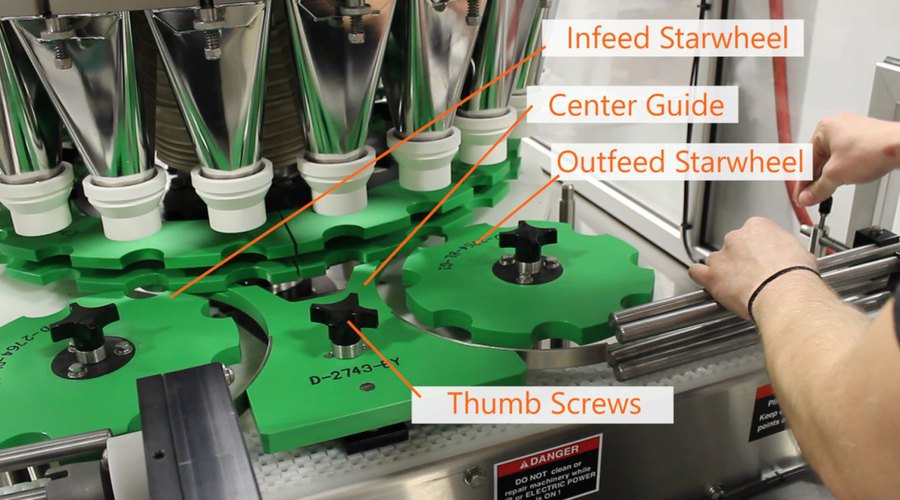

Although our rotary fillers are relatively simple, consumers are often intimidated by the term “change-over.” A change-over entails switching out key container-handling components to enable the filler to run multiple size containers. These product handling components consist of: Conveyor Guide Rails, Timing Screw, In-feed and Out-feed Star Wheels, Center Guide, Inner and Outter Container Handling Guiderails, Z-Seals, Transfer Funnels, and the Exit Conveyor Guide Rails.

This may seem daunting due to the fact that the machine must be down (not in production) in order to change-over, however a well-versed operator or two can perform a change-over in under 20 minutes. It is of utmost importance to complete each step of the change-over in proper order to ensure it gets finished as quickly as possible. After performing hundreds of change-overs here at All-Fill, we believe we have it down to a science! If you are considering a rotary application, or already have a rotary in your facility, please take a look at this video of a proper change-over.

Please contact All-Fill at (610)524-7350 for more information, or your regional salesperson/local sales representative directly.